-

From design to production. A full range of possibilities from Converis.

-

Excellent quality at every stage of cooperation.

-

Technology you can trust.

›

‹

- 1

- 2

- 3

The mission of our company is to offer high quality design, implementation and serial production services using rotomoulding for a wide group of customers at home and abroad.

Converis was established in September 2010 as a new entity in the plastics processing sector.

Our customer relations are built on mutual trust and the readiness to cooperate in reaching the established goals.

Our staff have many years of experience in rotomoulding, guaranteeing the best quality in production and customer service.

Our business is based on cooperation

with leading manufacturers of rotomoulding machines to ensure the highest technological standards. We source the raw materials used in production from renowned European manufacturers.

What we offer is intended for manufacturers of industrial products, machines, vehicles, interior design elements as well as other products made of rotomoulded plastic elements.

DISCOVER THE TECHNOLOGY THAT SATISFIES

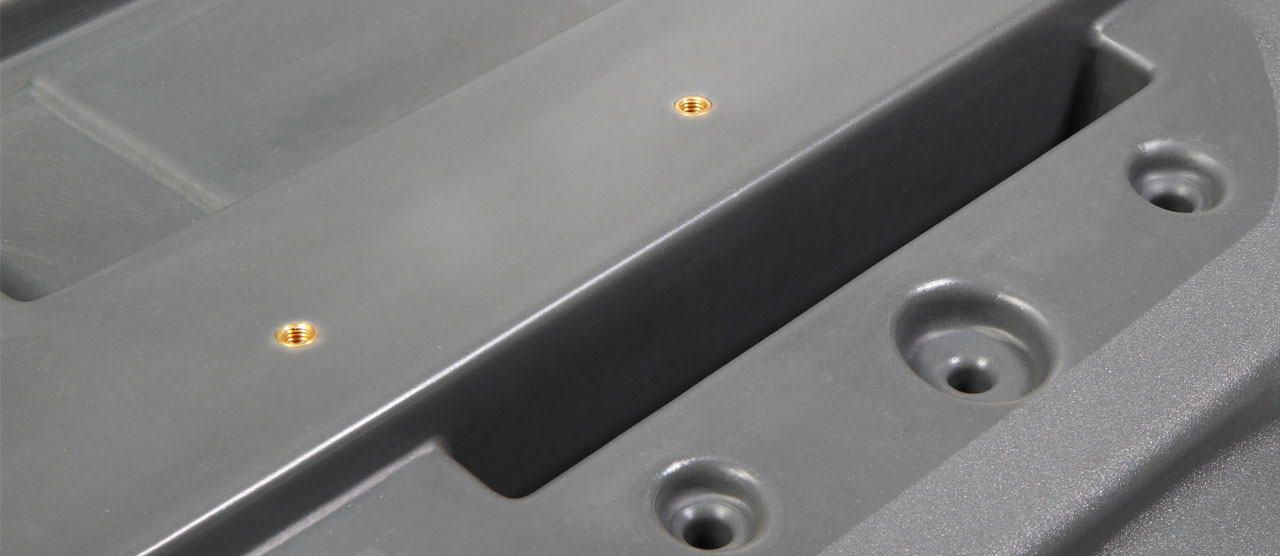

ROTOMOULDING aids in the manufacture of different plastic elements. The advantages of the technology include small internal stress of the products and the relatively low cost of the required components, such as moulds. Rotomoulding is also the most economical manufacturing process for large products (vol. > 2 m3).

HOW IS ROTOMOULDING USED IN PRACTICE?

The production process involves filling a mould, which is composed of two or more parts, with an appropriate quantity of powder or granulate, and then heating it to a high temperature while rotating it around two perpendicular axes. This rotation of the mould continues during the next stage of the process, i.e. during cooling of the mould. Once the process is complete, the mould is opened and the solidified single-layer monolithic product removed.

HIGH-END SOLUTIONS

Rotomoulding machines are available in different sizes, usually depending on the mould size. A typical machine usually consists of a heating chamber, cooling chamber and a set of arms to control the rotational movement of the moulds while in the chambers. The moulds are made from steel or aluminium. Depending on the shape of the end product, the moulds differ in their degree of complexity, which consequently affects the cost of their manufacture. The cheapest steel moulds tend to be used for relatively simple shapes, while aluminium moulds (cast or machined to the desired shape) help to obtain more complex shapes, providing excellent grounds for designing novel products.

Rotomoulding is usually associated with the production of large tanks, although it is also successfully used to produce complicated technical elements, components for machines and other equipment as well as products that have to satisfy high aesthetic requirements, such as toys as well as interior and garden design elements like lamps and furniture.

GAIN AN ADVANTAGE, CHOOSE ROTOMOULDING

The major advantages of rotomoulding are:

Converis Sp. z o.o.

ul. Kazimierza Wielkiego 61A

66-300 Międzyrzecz

NIP 5961736489REGON 080473992KRS: 0000367270

Tel/Fax: +48 95 720 56 24

e-mail: kontakt@converis.pl